Ask us

your question!

Which low loader bed do I choose?

Our low loaders are available with different types of beds. Depending on your load, you can choose the bed that best suits your operations. Read more about our beds and options below.

two beam bed

Linkable two beam bed

Agri-bed

Chalet-bed

More information on our dolly low loader beds can be found here.

Two beam bed

With the two beam bed, you have a universal and multifunctional bed for markets where height is a factor, such as construction machinery, building materials, wind and boat transport.

The single extendable two beam bed has a relatively low deadweight, leaving plenty of useful payload. Weight has also been saved because the beams are not linkable. The two beam bed makes it possible to load for instance a tank/silo or boat lower. In combination with the two beam neck, there is room for protruding load (drawbar), reducing the need to extend. The outer beams are fitted with certified 10t lashing eyes, the inner beams with positions for boltable lashing eyes. Various beam heights are available, depending on the desired load capacity.

A fixed wooden floor or a three-part removable floor panel set is optionally available, creating a completely flat loading floor in length and width. Even when extended, the removable floor boards can remain between the outer tubes.

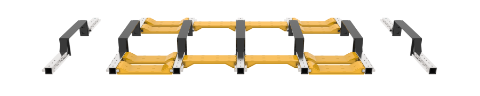

Linkable two beam bed

This bed is very similar to the two beam bed mentioned above, but is well suited for voluminous longitudinal transports such as feed silos, kettles, due to the possibility of linking loose beams.

Compared to our non-linkable two beam bed, this bed has a higher tare weight. Because the beams have compression joints at the rear side, it is possible to use optional extra beams. Apart from that, this bed is similar to the non-linkable two beam bed.

The beams can be extended between the bed and the axle set with linkable beams to create more loading length in the lowbed. The linkable beams are available in various lengths. By using coupling ears, the prestressment can also be adjusted.

A fixed wooden floor or a three-part removable floor panel set is optionally available, creating a completely flat loading floor in length and width. Even when extended, the removable floor boards can remain between the outer tubes. Floor panels are not possible in the extra connectable beams.

Agri-bed

The agri-bed is mainly used for transporting agricultural machinery such as tractors, combines, sprayers and self-loading wagons.

You choose a central beam if you need to transport machines where the wheels or tracks come next to the beam and can easily be removed by jacking the machine to reduce width and/or height. Both the outer and inner beams are fitted with positions for boltable lashing eyes, allowing the load to be properly secured. The central beam, which can only be extended at the front, is not linkable. In combination with a two beam agri-neck, space is created for inserting the drawbar of an agricultural trailer, eliminating or reducing the need to extend.

With optional reversible mattresses, the central beam can be used as a lowered flat loading floor or as a loading floor with 'wheel wells'. These wheel wells can be created in several positions, allowing agricultural machines with varying wheelbases to be transported even lower. Furthermore, the mattresses can be widened incrementally from 2,530 to 2,990 mm.

Chalet-bed

For transporting chalets that can be moved on wheels, we have developed a special chalet bed to enable independent loading/unloading.

The neck is detachable from the bed, allowing the chalet to be driven on and off the bed via the folding ramp at the front. The loading floor is lowered on the outer sides; on this, the wheels of the chalet, or other movable living forms, will be lowered, limiting the height. The bed is extendable at the rear only to a maximum bed length of 16,000 mm. Furthermore, the bed has 10T certified lashing eyes in the right places for safely securing the load.

We are keen to help you make the right choice. Contact one of our advisers for solid advice and a no-obligation quotation.